Time to Burn?

Peter R. Robichaud, Jim Bilskie

Prescribed fires increasingly are

being used to reduce hazardous fuels, a major objective of the National Fire

Plan. However, despite advancing technology and ever-improving models, determining

the best time for a prescribed burn is still a challenge.

After gathering data and applying models, the

fire manager may pick up a bit of duff, or organic material, squeeze it firmly

and check the moisture before giving approval to begin the burn. The fire manager

uses past experience, weather information and a "feel" for the current

conditions as a final check.

The effect of fire on the forest floor can vary

from merely removing the litter to totally consuming the duff, which exposes

the mineral soil and alters the surface soil structure. Fire managers often

design prescribed fires to leave a portion of residual duff material to protect

the mineral soil. Duff thickness and moisture content are the most important

factors in determining duff consumption during fires. Using a measured duff

moisture content in models like the

First Order Fire Effects Model

from the USDA Forest Service, fire managers can improve the estimate of duff remaining

after a burn.

Now there is an additional tool available. The

DMM600 duff moisture meter provides reliable, real-time measurements of duff

moisture content.

|

HOW

IT WORKS

In comparison to other woody fuels, duff moisture content has greater spatial

and temporal variation. Small precipitation events and heavy dew accumulations

that have negligible effect on the moisture content of large fuel can significantly

increase the moisture content of fine fuels and litter. Subsurface duff

can lose moisture through evaporation much more quickly than the large woody

fuels. Due to subtle differences in canopy closure, slope, aspect and micro-topography,

duff moisture levels can vary significantly across the landscape, even at

the hill slope scale. These variations make it important to use real-time

duff moisture measurements to estimate duff consumption and, more importantly,

desired post-fire duff depths. |

Basic field use.

The sample is collected from the portion of the duff layer just above the soil

mineral horizon and is pushed through a No. 4 mesh

sieve that fits in the opening of the sample chamber. Passing the duff through

the sieve breaks up large organic fragments and removes sticks and rocks to

allow for more uniform packing. Once the sieved material fills the chamber,

the cap is put on and the compression knob turned until an audible indicator

signals the sample is properly compressed. Upon proper compression, the instrument

automatically takes the measurement, which is immediately visible in the display

at the base of the instrument. Readings are displayed in real-time only; measurements

are not stored. Total time needed to sieve and measure each sample is about

30 seconds.

Operation

principles. The tough, lightweight DMM600 is a portable, battery-powered

sensor that was developed from frequency domain reflectometry technology, commonly

known as FDR. When proper pressure triggers a measurement, a high-frequency

signal of 42MHZ is applied to the wave guide at the base of the sample chamber,

and the sensor electronics detect the change in frequency of the reflected signal.

The frequency change depends on the dielectric constant of the medium adjacent

to the wave guide. Since the dielectric constant of the medium varies with moisture

content, the frequency change can be easily related, through a simple calibration

function, to provide a moisture content measurement. The unit's microprocessor

uses a factory-supplied calibration to convert the frequency to a volumetric

moisture content and displays the value in the LCD readout.

Air

voids in the organic material may reduce the apparent dielectric constant and/or

create a poor contact between the duff and the waveguide located at the base

of the sample chamber. Using the meter's compression feature on sieved duff

ensures each sample is pressed evenly against the wave guide, which reduces

measurement variability. An audible signal tells the user when correct compression,

15 pounds, is applied and the measurement is complete.

DMM600 meter accessories

- CD-ROM containing video instruction, PCDMM software, instruction manual and Excel spreadsheet for calibrations

- Softsided, padded carrying case with screwdriver and spare 9-volt battery

- 6-foot, 9-pin serial cable

|

|

Specifications

| Size: |

3-1/2 inch diameter

10 inch length |

| Weight: |

3.7 pounds |

| Sieve:

| No. 4 mesh, .203 inch

3-inch diameter |

| Battery: |

9-volt alkaline |

| Battery life: |

Over 2,000 uses |

| Accuracy: |

±5% for full-scale range |

| Resolution: |

1% volumetric

moisture content |

|

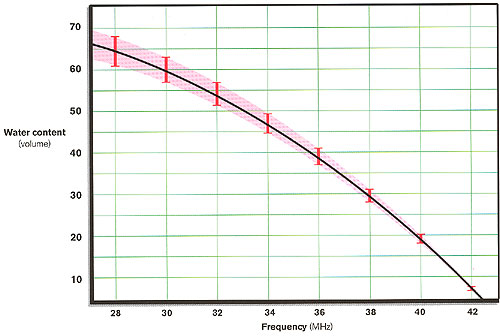

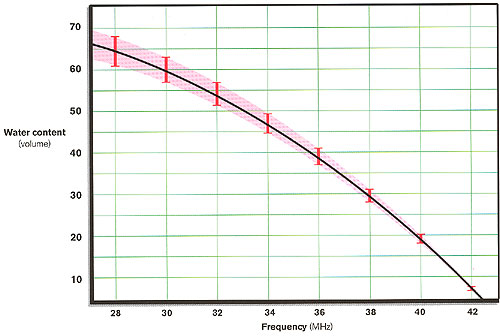

Calibration.

The factory-supplied calibration for the DMM600 is derived from laboratory measurements

of the volumetric moisture content of duff from eight different forested sites.

Given the elevation differences of these sites, the cover species varied to

include

spruce (Picea engelmannii),

alpine fir (Abies lasiocarpa),

lodgepole pine (Pinus contorta),

larch (Larix occidentalis),

ponderosa pine (Pinus ponderosa) and

Douglas-fir (Pseudotsuga menziesii).

Because the individual calibration curves were similar, the data were combined to develop

a single, standard calibration curve (see below.) The error bars indicate that

the measurement accuracy decreases as moisture content increases. The accuracy

is approximately ± 4% at 60% volumetric moisture content and approximately

±1.5% at 30% volumetric moisture content. It's recommended that the average

of samples from several nearby locations be used to reduce the effects of natural

variability.

The meter's response to changing moisture content is best described with a quadratic

calibration equation

Volumetric

moisture content = 5.288 + 5.905 (frequency) - 0.142 (frequency2)

where frequency is the DMM600 readout in megahertz. User-derived calibrations

can be determined using the laboratory procedures described in the DMM600

instruction manual and the DMM600 calibration Excel spreadsheet provided

in the PCDMM software package. User-defined calibrations are entered into

the PCDMM interface and loaded to the DMM600 through a serial port connection.

Studies done on eastern hardwood duff from Massachusetts show little deviation

from the standard calibration curve. It is likely that the standard calibration

curve will meet the needs of most fire managers across a range of vegetation

types. |

DMM600 standard calibration curve

The variability is smallest in the lower moisture/higher frequency area of the curve, where accuracy is most critical.

|

Volumetric versus gravimetric.

The basic operation of the DMM600 gives the volumetric moisture content of the sampled

duff. Using a simple calibration process, the gravimetric, dry weight-based

moisture content — the measurement most commonly used by fire managers

— can be added to the instrument readout.

A

value for duff bulk density is needed for this calibration process. Fire managers

may choose to use a known bulk density value or determine one from local conditions,

using the equation bulk density = dry weight/volume.

Each coefficient in the standard calibration equation is divided by the bulk

density.

The

three gravimetric coefficients are entered into the PCDMM software and uploaded

to the DMM600 via a serial port connection on the base. Because duff bulk density

is relatively constant, this calibration process can be completed prior to going

to the field to make duff moisture measurements. When each field measurement

is made, the standard volumetric moisture content and the user-defined gravimetric

moisture content are alternately displayed in the readout.

Duff moisture content is critical

information for fire managers making operational and planning decisions for

prescribed burns. The DMM600 duff moisture meter provides dependable duff moisture

content data in the field and for input in predictive modeling programs.

The portable electronic duff moisture meter provides duff moisture data in the field.

Peter R. Robichaud, Ph.D., P.E., is

a research engineer at the USDA Forest Service Rocky Mountain Research Station

in Moscow, Idaho. He can be reached at the Forestry Sciences Laboratory, Rocky

Mountain Research Station, 1221 S. Main St., Moscow, Idaho 83843; 208-883-2349;

e-mail: probichaud@fs.fed.us.

Jim Bilskie, Ph.D., is the soil physicist

at Campbell Scientific Inc., Logan, Utah.

The use of trade or firm names in this publication is for reader information

and does not imply endorsement by the U.S. Department of Agriculture of any

product or service.

This manuscript was written and prepared

by a U.S. government employee on official time and therefore is in the public

domain and not subject to copyright.

Originally published as:

Robichaud, P.R.; Bilskie, J. 2003. Time To Burn? Wildfire, May/June 2003. International Association of Wildland Fire.